The Importance of UL Certification for Automation Control Panels

UL Certification plays a crucial role in ensuring the safety, reliability, and regulatory compliance of automation control panels. UL (Underwriters Laboratories) is a globally recognized independent safety certification organization that tests and certifies products, systems, and components for safety standards. For automation control panels, UL certification ensures that the panel meets stringent safety requirements, which is essential for reducing risks, preventing hazards, and complying with local and international regulations. Here’s why UL certification is important for automation control panels:

1. Ensuring Safety and Reducing Risks

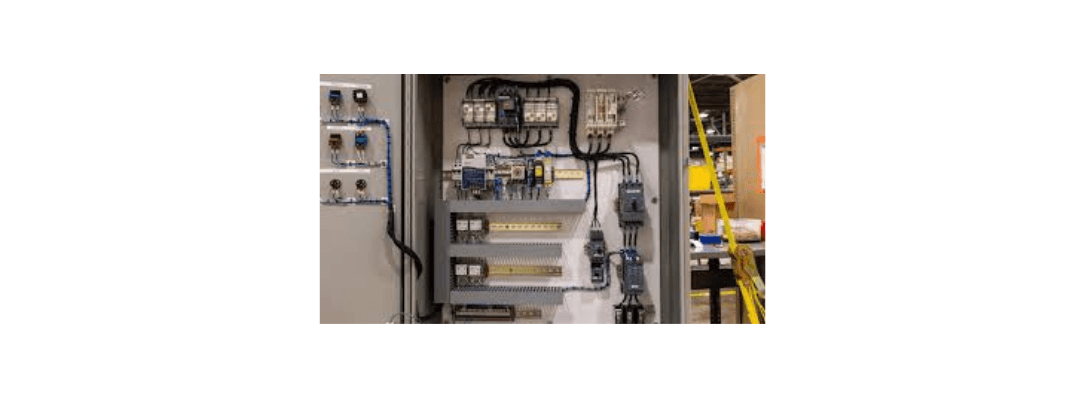

- Preventing Electrical Hazards: Automation control panels often manage complex electrical systems that include high voltages, currents, and various components like relays, transformers, switches, and circuit breakers. UL certification ensures that these components and their wiring are installed and configured safely, reducing the risk of electrical fires, short circuits, and shocks.

- Equipment Safety: By adhering to UL standards, the design, construction, and operation of automation control panels are validated to ensure they prevent overheating, arc flash incidents, or other dangerous conditions that could lead to equipment damage or safety risks for operators.

2. Compliance with Industry Standards

- UL 508A Certification: UL 508A is the standard for Industrial Control Panels in the United States and specifies the construction requirements for panels used in industrial and commercial applications. UL 508A certification ensures that automation control panels comply with North American safety standards, particularly in terms of wiring methods, component use, and panel design.

- Meeting Regulatory Requirements: Many industries, including manufacturing, oil and gas, energy, and water treatment, require UL-certified control panels to meet regulatory requirements. Without UL certification, companies may face compliance issues, penalties, or delays in project approvals.

- International Standards: UL certification also helps meet international standards, such as CE marking in Europe and CSA standards in Canada, making UL-certified panels suitable for use in multiple regions.

3. Improving Product Reliability and Quality

- Thorough Testing: UL-certified automation control panels undergo rigorous testing to ensure that they can withstand real-world operating conditions. This includes tests for temperature, humidity, vibration, and electrical load. As a result, UL-certified panels are more reliable, reducing the likelihood of malfunctions or system failures.

- Quality Assurance: UL certification is a mark of quality, as it ensures that only approved components are used in the panel design. This improves the overall performance of the control panel and enhances its durability over time.

4. Facilitating Insurance and Liability Protection

- Easier Insurance Approval: Many insurance companies prefer or require UL-certified products because they meet recognized safety standards. UL certification helps businesses obtain insurance for their facilities, operations, and equipment more easily and at lower premiums.

- Limiting Liability: In the event of an accident, having a UL-certified control panel can protect a business from liability claims. Since the panel has been tested and approved for safety, companies can demonstrate that they have taken appropriate measures to ensure a safe operating environment, reducing the risk of litigation or costly fines.

5. Simplifying Inspections and Approvals

- Compliance with Local Codes: Many local and regional electrical codes and standards (such as the National Electrical Code (NEC) in the U.S.) require UL certification for automation control panels. A UL mark on the panel simplifies the inspection and approval process during construction, installation, and commissioning phases.

- Faster Permitting and Approvals: Since UL-certified control panels meet established safety standards, project permitting and approvals from authorities having jurisdiction (AHJs) are often faster and more straightforward. This reduces project delays and ensures smooth operations.

6. Enhancing Operational Safety

- Operator Protection: UL certification ensures that control panels include safety mechanisms such as proper grounding, insulation, and fault protection devices (e.g., circuit breakers, surge protectors). These features protect operators from electrical shocks, equipment failures, and other hazards.

- Arc Flash and Overcurrent Protection: UL-certified panels are designed with overcurrent protection and other safety measures to minimize the risks of arc flash incidents, which can cause serious injuries or damage equipment. These safety features are critical for ensuring a safe work environment, especially in high-risk industries like oil and gas, chemical processing, and manufacturing.

7. Global Market Access and Acceptance

- International Trade: UL certification is recognized not only in the United States but globally. For companies that manufacture, export, or install automation control panels in international markets, UL certification ensures that the products meet global safety standards, opening up opportunities for international business.

- Cross-Market Certification: UL certifications can often serve as the basis for achieving other regional certifications (e.g., CE marking or CSA certification). This streamlines the certification process and reduces costs for manufacturers and system integrators working in multiple markets.

8. Long-Term Cost Savings

- Reduced Maintenance and Downtime: UL-certified control panels are designed to function safely and reliably over time, reducing the need for frequent repairs or replacements. This lowers maintenance costs and minimizes system downtime, resulting in higher productivity and cost savings for businesses.

- Avoiding Penalties: Failing to use UL-certified panels in regions where they are required can result in costly penalties, shutdowns, or legal action. Investing in UL-certified panels upfront helps companies avoid these risks and ensure continuous, safe operation.

9. Boosting Customer Confidence

- Trust and Credibility: UL certification is a well-established indicator of safety and quality. When customers and stakeholders see the UL mark on a control panel, it reassures them that the panel has been thoroughly tested and meets the highest safety standards. This builds trust in the product and the company providing it.

- Competitive Advantage: Offering UL-certified automation control panels gives companies a competitive edge, especially in industries where safety and compliance are paramount. UL certification demonstrates a commitment to quality, safety, and reliability, which can be a key selling point in bids and negotiations.

Conclusion

UL certification is essential for ensuring the safety, compliance, and performance of automation control panels. It provides confidence that the panel meets stringent safety standards, protects operators, and reduces risks of electrical hazards and equipment failures. UL-certified panels also help businesses comply with regulatory requirements, facilitate faster project approvals, reduce liability risks, and improve long-term operational efficiency. Whether you’re involved in manufacturing, oil and gas, energy, or any other industry, choosing UL-certified control panels is an investment in safety, reliability, and peace of mind.

Recent Comments