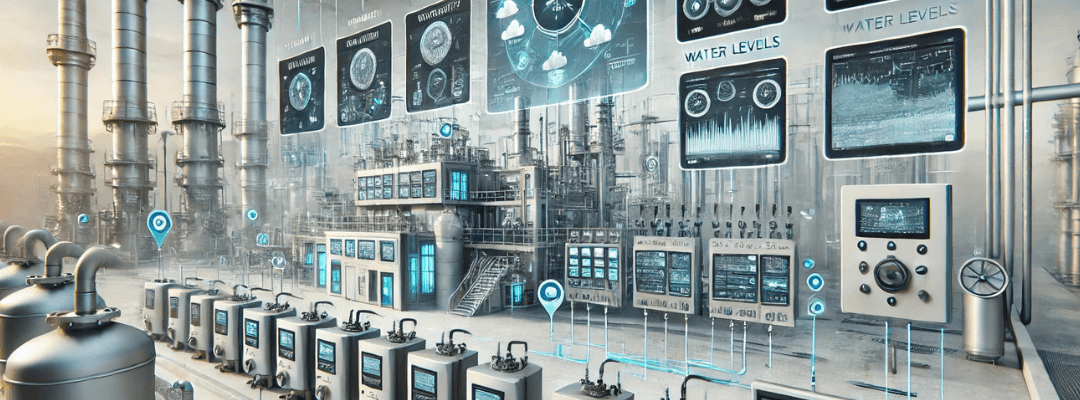

Environmental Monitoring with Automation Control Panels: Ensuring Compliance and Efficiency

Automation control panels are increasingly vital in environmental monitoring across industries, ensuring regulatory compliance and enhancing operational efficiency. By automating the monitoring of environmental factors such as air quality, water discharge, emissions, and waste management, control panels help industries maintain safe environmental practices while optimizing resource use. Here’s how automation control panels contribute to environmental monitoring, compliance, and efficiency:

1. Real-Time Data Collection and Monitoring

- Continuous Monitoring: Automation control panels continuously monitor key environmental parameters such as air quality, water pH levels, emissions, temperature, humidity, and pollutant levels. Real-time data is collected from sensors and fed into the control panel, providing immediate insights into environmental conditions.

- Instant Data Access: With real-time monitoring, industries can quickly access environmental data, ensuring that any deviation from established limits is immediately detected. This helps operators respond swiftly to potential environmental hazards, reducing the risk of non-compliance or safety issues.

- Remote Monitoring: Automation control panels often integrate with remote monitoring systems, allowing environmental conditions to be tracked from a central location or via mobile devices. This enables faster response times and better oversight, even in remote or difficult-to-access areas.

2. Ensuring Regulatory Compliance

- Compliance with Environmental Regulations: Automation control panels ensure that companies comply with environmental regulations such as EPA standards, ISO 14001, and other local or international environmental guidelines. By monitoring pollutants, emissions, and other environmental factors, control panels help ensure that environmental limits are respected.

- Automated Reporting: Automation systems can generate automatic reports on environmental data, which are critical for demonstrating compliance during audits or inspections. These reports provide documented proof that the company is adhering to environmental standards, helping avoid fines, penalties, or operational shutdowns.

- Emission Control: For industries with strict emission regulations, control panels automate emission monitoring and control. For example, in power plants or manufacturing facilities, control panels can monitor CO2, SO2, or NOx levels and adjust the operation of scrubbers, filters, or other emission control systems to stay within regulatory limits.

3. Energy Efficiency and Resource Optimization

- Optimizing Energy Use: Automation control panels help optimize the use of energy-intensive equipment such as HVAC systems, pumps, and motors by adjusting their operation based on real-time environmental data. For instance, in facilities where temperature control is essential, automation systems can reduce energy consumption by adjusting HVAC settings based on occupancy and temperature fluctuations.

- Water Management: For industries that rely heavily on water (e.g., agriculture, food processing, or chemical plants), automation control panels can optimize water usage. By monitoring water flow, quality, and consumption, control systems can prevent overuse, reduce waste, and ensure efficient water management.

- Reducing Environmental Footprint: Automation systems also help industries reduce their environmental footprint by integrating renewable energy sources, controlling emissions, and optimizing resource use. For example, integrating solar panels or wind turbines into the control panel can reduce reliance on non-renewable energy sources, contributing to sustainability goals.

4. Wastewater and Effluent Management

- Water Quality Monitoring: Automation control panels are essential for monitoring the quality of wastewater and effluent in industries such as pharmaceuticals, chemicals, and food processing. By continuously measuring parameters such as pH, turbidity, temperature, and dissolved oxygen, automation systems ensure that discharged water meets regulatory standards before being released into the environment.

- Automated Effluent Treatment: Control panels can automate wastewater treatment processes, adjusting chemical dosing, filtration, or aeration based on the quality of the water being treated. This ensures that treatment systems operate efficiently, minimizing the risk of non-compliant discharges that could harm the environment.

- Real-Time Alerts: If water quality parameters fall outside the acceptable range, the control panel can send real-time alerts to operators, enabling them to take immediate corrective action. This minimizes the risk of environmental violations and helps protect local ecosystems.

5. Air Quality Control

- Monitoring Industrial Emissions: Automation control panels can be integrated with air quality sensors to monitor emissions such as particulate matter, volatile organic compounds (VOCs), and harmful gases (e.g., carbon monoxide, nitrogen oxides). In industries such as manufacturing, mining, or oil and gas, this is essential for ensuring that emissions remain within legal limits.

- Ventilation and Filtration Control: In environments where air quality is critical (e.g., cleanrooms, laboratories, or hazardous material processing plants), automation control panels manage ventilation and filtration systems. By monitoring air quality, the system automatically adjusts airflow, filters, or scrubbers to maintain a safe and compliant work environment.

6. Predictive Maintenance for Environmental Equipment

- Predicting Equipment Failure: Control panels continuously monitor the performance of critical environmental equipment, such as air filtration systems, water pumps, and chemical dosing units. By analyzing data like motor vibration, temperature, and flow rates, the system can predict when equipment is likely to fail and schedule maintenance before a breakdown occurs.

- Reducing Downtime and Environmental Risks: Predictive maintenance helps prevent unexpected equipment failure, reducing the risk of non-compliant emissions or water discharge due to malfunctioning environmental control equipment. This ensures that environmental protection systems are always operating at peak efficiency.

7. Automation for Hazardous Waste Management

- Managing Toxic or Hazardous Waste: Automation control panels help manage the safe handling, treatment, and disposal of hazardous waste materials. By monitoring storage conditions (e.g., temperature and pressure) and automating the dosing of neutralizing agents or filtration processes, the control panel ensures that waste is treated in accordance with environmental regulations.

- Safety Systems for Hazardous Areas: In industries that deal with hazardous materials, control panels integrate safety interlocks and emergency shutdown systems (ESD) to prevent spills, leaks, or accidents that could harm the environment. If unsafe conditions are detected, the control panel can automatically trigger alarms or initiate safety protocols to mitigate environmental risks.

8. Integration with SCADA Systems for Environmental Oversight

- SCADA Integration: Supervisory Control and Data Acquisition (SCADA) systems are often integrated with automation control panels to provide centralized monitoring and control of environmental conditions across multiple facilities. This enables operators to track air quality, emissions, water discharge, and other environmental factors in real time from a central control room or remote location.

- Centralized Data Collection: By integrating multiple sensors and control panels into a SCADA system, industries can gather comprehensive environmental data across their operations. This data can be analyzed to identify trends, improve environmental performance, and ensure compliance with environmental standards.

9. Reducing Environmental Incidents and Response Time

- Early Detection of Environmental Hazards: Automation control panels can detect environmental issues, such as air pollution spikes or water contamination, early. This allows companies to take proactive measures before the issue escalates into a significant environmental incident, helping to avoid fines, reputational damage, and harm to the local community.

- Faster Response to Emergencies: Control panels equipped with real-time monitoring and alarm systems allow for immediate response to environmental emergencies. If hazardous emissions or waste are detected, the system can automatically initiate emergency protocols, such as shutting down affected equipment or activating containment systems.

10. Automated Environmental Reporting

- Automated Data Logging: Automation control panels record environmental data over time, generating detailed logs that can be used for regulatory reporting or internal environmental management programs. These records provide an accurate account of the facility’s environmental impact, supporting compliance efforts and improving transparency.

- Simplified Compliance Reporting: Automated environmental monitoring systems streamline the reporting process, reducing the time and effort required to submit compliance documentation. By automatically generating reports on emissions, water quality, waste management, and energy use, companies can ensure that they meet regulatory deadlines and avoid compliance penalties.

11. Energy and Resource Management in Sustainable Buildings

- Sustainable Building Management: In green buildings and eco-friendly industrial facilities, automation control panels manage energy use, water consumption, and waste reduction systems to meet sustainability goals. For example, automated lighting and HVAC systems can be adjusted to reduce energy consumption, while water reuse and recycling systems are optimized based on real-time data.

- LEED and ISO 14001 Certification: Automation systems that help track and reduce a facility’s environmental impact can contribute to achieving certifications such as LEED (Leadership in Energy and Environmental Design) or ISO 14001 (Environmental Management Systems). These certifications demonstrate a commitment to sustainability and environmental stewardship.

Conclusion

Automation control panels are a critical tool for environmental monitoring, ensuring regulatory compliance and improving operational efficiency across a range of industries. By automating the monitoring and control of emissions, water quality, waste management, and air filtration, these systems help reduce environmental risks, minimize energy consumption, and optimize resource use. Moreover, the integration of control panels with SCADA systems and predictive maintenance strategies enables businesses to maintain safe, compliant, and efficient operations, while supporting sustainability goals and reducing their environmental footprint.

Recent Comments