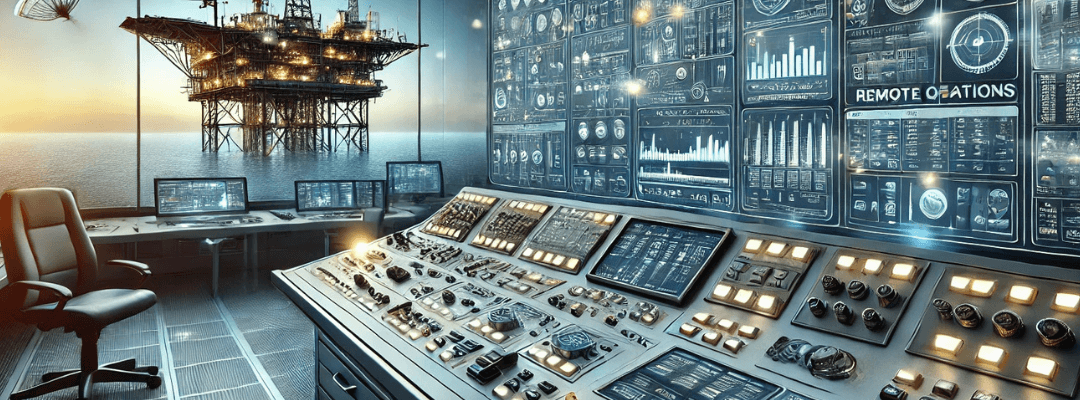

Automation Control Panels for Remote Operations: Managing Offshore and Remote Sites

Managing offshore and remote sites, such as oil rigs, wind farms, mining operations, and other isolated facilities, requires robust and reliable automation control systems. Automation control panels play a critical role in enabling the efficient and safe operation of these sites by providing remote monitoring, control, and diagnostics. These panels help reduce the need for on-site personnel, lower operational costs, and improve responsiveness to issues. Here’s how automation control panels support remote operations:

1. Remote Monitoring and Control

- Real-Time Data Access: Automation control panels in offshore and remote sites are equipped with communication interfaces that allow real-time data transmission to a central control room or monitoring center. This enables operators to remotely monitor equipment status, environmental conditions, and production processes from a distant location.

- Remote Control: Control panels allow operators to remotely adjust equipment settings, start or stop machinery, and fine-tune processes as needed. This is essential for managing operations in remote areas where it is not feasible to have personnel on-site 24/7. For example, an offshore oil platform can be remotely monitored, with pump speeds, drilling operations, and safety systems adjusted in real time.

- SCADA Integration: Remote operations often rely on Supervisory Control and Data Acquisition (SCADA) systems integrated with automation control panels. SCADA systems provide a centralized platform for monitoring multiple remote sites, offering a comprehensive view of all operations and the ability to control equipment across locations from a single interface.

2. Ensuring Operational Efficiency

- Reducing On-Site Personnel: One of the key benefits of automation control panels for remote sites is the ability to reduce the need for on-site personnel. By enabling remote management of equipment, fewer staff are required to be physically present, reducing labor costs and minimizing risks associated with working in hazardous or isolated environments.

- Optimizing Production: Automation control panels enable the continuous monitoring of key performance indicators (KPIs), such as production output, equipment performance, and energy consumption. By analyzing this data in real time, operators can make adjustments to optimize production efficiency, even from thousands of miles away.

- Load Balancing and Resource Management: For remote energy sites like wind farms or solar power plants, automation control panels help manage energy output and load balancing based on real-time demand. This ensures that power is distributed efficiently and that energy generation is optimized to meet grid requirements.

3. Predictive Maintenance and Remote Diagnostics

- Condition Monitoring: Automation control panels continuously monitor the health of critical equipment, such as motors, turbines, pumps, and compressors. Sensors track parameters like vibration, temperature, pressure, and flow rates, allowing operators to assess the condition of equipment in real time.

- Predictive Maintenance: Using data from sensors, control panels can predict when equipment is likely to fail, allowing for maintenance to be scheduled before a breakdown occurs. This proactive approach reduces unplanned downtime, minimizes repair costs, and extends the lifespan of equipment, which is especially critical for remote sites where access may be difficult or time-consuming.

- Remote Troubleshooting: In the event of a fault or malfunction, automation control panels enable remote diagnostics, allowing technicians to troubleshoot issues from a central location. This reduces the need for on-site visits and ensures that problems are addressed quickly, minimizing downtime.

4. Enhanced Safety and Risk Management

- Emergency Shutdown Systems (ESD): Automation control panels for remote and offshore sites often integrate Emergency Shutdown Systems (ESD) that can automatically trigger shutdowns in response to dangerous conditions, such as gas leaks, fires, or equipment malfunctions. This ensures that operations are safely halted to protect personnel and assets.

- Safety Monitoring: Control panels continuously monitor safety-critical parameters, such as pressure in pipelines, gas levels, or the integrity of structural systems, and send real-time alerts to operators. If abnormal conditions are detected, the system can take automated actions to mitigate risks, including triggering alarms, shutting down equipment, or activating fire suppression systems.

- Remote Safety Interventions: In hazardous environments, like offshore oil rigs or mining operations, automation control panels allow for remote safety interventions. Operators can initiate safety protocols, shut down equipment, or activate emergency systems without being physically present at the site, reducing the risk to human life.

5. Environmental Monitoring and Compliance

- Monitoring Emissions and Discharges: Remote and offshore sites often operate in environmentally sensitive areas, requiring strict monitoring of emissions, water discharges, and pollutant levels. Automation control panels are equipped with environmental sensors to track parameters such as CO2 emissions, methane leaks, or water quality. This ensures compliance with environmental regulations and minimizes the environmental impact of operations.

- Automated Reporting: Control panels can generate automated environmental reports that provide accurate, real-time data on emissions, water discharge, and other environmental factors. This simplifies compliance with regulatory bodies and ensures timely reporting, reducing the risk of fines or legal issues.

- Leak Detection and Response: In industries such as oil and gas, automation control panels monitor pipelines and storage tanks for leaks or spills. If a leak is detected, the system can automatically shut down valves, activate containment systems, and alert operators, minimizing the environmental damage.

6. Energy Efficiency and Power Management

- Energy Monitoring and Control: Remote operations, especially in isolated areas with limited power sources, require efficient energy management. Automation control panels monitor energy consumption in real time, optimizing the operation of power-intensive equipment like pumps, HVAC systems, and generators. This reduces energy waste and ensures that power is distributed where it is needed most.

- Integration with Renewable Energy Systems: Many remote sites, such as offshore platforms or isolated industrial facilities, integrate renewable energy sources like solar panels or wind turbines to supplement their energy needs. Automation control panels manage the flow of energy between renewable sources, energy storage systems, and the grid, optimizing energy use and reducing dependency on fossil fuels.

7. Communications and Connectivity

- Satellite and Wireless Communications: In remote and offshore locations where traditional wired communication is not feasible, automation control panels rely on satellite, radio frequency, or wireless communication networks to transmit data to central control centers. These networks ensure reliable data transmission and remote access, even in the most isolated environments.

- Redundancy and Failover Systems: To maintain connectivity in remote areas, automation control panels often incorporate redundant communication systems. If the primary communication link fails, the system can automatically switch to a backup link, ensuring continuous monitoring and control without interruptions.

8. Scalability and Flexibility

- Modular Control Systems: Automation control panels for remote operations are often designed with modularity in mind. This allows operators to easily expand or reconfigure the system as operational needs change. For instance, new equipment or production lines can be integrated into the control panel without requiring a complete system overhaul.

- Scalability for Multiple Sites: For companies managing multiple remote sites, automation control panels provide the scalability needed to oversee operations across a wide geographic area. This enables centralized monitoring of several sites, such as multiple offshore platforms or wind farms, through a single interface.

9. Weather and Environmental Monitoring

- Monitoring Harsh Conditions: Remote sites are often exposed to extreme weather conditions, such as high winds, heavy rainfall, and temperature fluctuations. Automation control panels are designed to monitor environmental conditions in real time, allowing operators to take preventive actions, such as shutting down equipment during storms or adjusting operations based on weather patterns.

- Proactive Response to Weather Events: Weather data can be integrated into automation control panels, enabling them to automatically adjust operations based on forecasts. For example, wind turbines can be adjusted or shut down in advance of a storm, and offshore oil rigs can prepare for adverse weather by securing equipment and reducing non-essential operations.

10. Cybersecurity and Remote Access

- Secure Remote Access: Given the growing reliance on remote monitoring and control, cybersecurity is a top priority for remote sites. Automation control panels incorporate secure communication protocols, such as VPNs and encrypted data transmission, to ensure that remote access to critical systems is protected against cyber threats.

- Firewalls and Intrusion Detection: To prevent unauthorized access, automation control panels for remote operations include robust firewalls and intrusion detection systems. These security measures help protect sensitive operational data and ensure that only authorized personnel can access or modify control settings.

Conclusion

Automation control panels are essential for efficiently managing offshore and remote sites, providing real-time monitoring, predictive maintenance, enhanced safety, and environmental compliance. By enabling remote control, reducing the need for on-site personnel, and ensuring the safe and efficient operation of equipment, automation systems help minimize costs and improve the reliability of operations in challenging environments. As industries continue to expand into more isolated and hazardous locations, automation control panels will play an increasingly important role in ensuring operational success and sustainability.

Recent Comments