Automation Control Panels for Remote Operations: Managing Offshore and Remote Sites

Automation control panels are critical for managing offshore and remote sites, such as oil and gas platforms, mining operations, wind farms, and remote industrial facilities. These environments often pose challenges due to their isolation, harsh conditions, and limited access to on-site personnel. Automation control panels enable remote monitoring, control, and diagnostics of critical systems, ensuring operational efficiency, safety, and sustainability in these difficult-to-reach locations. Here’s how automation control panels are essential for managing offshore and remote operations:

1. Real-Time Remote Monitoring and Control

- Continuous Monitoring: Automation control panels monitor and control key processes like power generation, temperature, pressure, and equipment performance. This real-time data is transmitted to a central control room, often located far from the remote site, allowing operators to oversee operations without needing to be on-site.

- Remote Adjustments: Operators can make real-time adjustments to equipment and processes, such as changing pump speeds, opening or closing valves, and regulating HVAC systems. This capability is critical for managing processes that need continuous oversight, such as oil drilling, gas extraction, or remote power generation.

- SCADA Integration: Control panels are often integrated with Supervisory Control and Data Acquisition (SCADA) systems to provide centralized monitoring of multiple remote sites. SCADA systems allow operators to manage geographically dispersed assets from a single interface, increasing efficiency and responsiveness.

2. Reducing On-Site Personnel Needs

- Automating Routine Operations: Automation control panels significantly reduce the need for on-site personnel by automating routine tasks such as equipment operation, monitoring, and reporting. This not only lowers labor costs but also minimizes the risks associated with working in hazardous environments, such as offshore oil rigs or mining sites.

- Remote Diagnostics: With the ability to monitor equipment health in real time, automation control panels can detect issues like abnormal vibrations, temperature changes, or pressure fluctuations. Remote diagnostics allow operators to troubleshoot problems without sending technicians to the site, reducing downtime and travel costs.

3. Predictive Maintenance and Reduced Downtime

- Condition Monitoring: Automation control panels continuously gather data from sensors monitoring critical parameters such as vibration, temperature, and motor performance. This data is analyzed to detect early signs of equipment wear or failure, allowing maintenance teams to address issues before they cause major disruptions.

- Predictive Maintenance: Predictive maintenance is especially valuable for remote sites where access to equipment may be limited. Automation control panels use sensor data to predict when equipment will need maintenance, allowing repairs to be scheduled proactively, thus avoiding unplanned outages and reducing repair costs.

- Reduced Downtime: By detecting and addressing issues early, automation systems help to minimize downtime. For offshore or remote sites where repairs can be difficult or delayed due to logistical challenges, this is particularly important for maintaining operational continuity.

4. Enhanced Safety in Hazardous Environments

- Emergency Shutdown Systems (ESD): In remote and offshore environments, automation control panels are often integrated with Emergency Shutdown Systems (ESD) that can automatically stop operations in response to unsafe conditions, such as equipment failures, gas leaks, or fires. This capability is critical for protecting personnel and assets.

- Remote Safety Controls: Operators can remotely initiate safety protocols, such as shutting down specific equipment, activating alarms, or adjusting environmental controls, in response to hazardous conditions. This ensures quick action without requiring personnel to be present in potentially dangerous situations.

- Continuous Safety Monitoring: Automation control panels continuously monitor environmental conditions like temperature, pressure, gas levels, and structural integrity. If unsafe conditions are detected, the system automatically triggers alerts, allowing operators to intervene before an incident occurs.

5. Environmental Monitoring and Compliance

- Emission Control: Automation control panels monitor emissions and discharges to ensure compliance with environmental regulations. They track CO2, methane, or particulate emissions and adjust processes to keep emissions within permissible limits, helping remote sites avoid regulatory penalties and maintain environmental sustainability.

- Water and Waste Management: In offshore platforms or remote industrial sites, control panels can automate the monitoring and treatment of water discharge, ensuring that wastewater is treated before being released. This helps comply with environmental regulations while protecting local ecosystems.

- Leak Detection: Automation systems for remote oil and gas pipelines or storage tanks include sensors for detecting leaks or spills. The control panel automatically initiates emergency protocols, such as shutting down valves or activating containment measures, to prevent environmental damage.

6. Energy Management and Efficiency

- Optimizing Energy Use: In remote locations, where energy supply can be limited, automation control panels optimize energy usage by adjusting the operation of energy-intensive systems like pumps, motors, HVAC systems, and generators. This ensures that energy is used efficiently, reducing operational costs and extending the life of energy resources like fuel or renewable energy storage.

- Integration with Renewable Energy: Many remote sites use renewable energy sources such as solar panels or wind turbines. Automation control panels manage energy generation and storage, ensuring that renewable energy is efficiently used to power equipment while minimizing reliance on fossil fuels.

- Load Shedding and Peak Shaving: Automation systems can implement load-shedding strategies to reduce non-essential energy use during peak demand periods. By balancing energy loads, these systems help prevent power outages and reduce the overall energy costs of remote operations.

7. Communications and Connectivity

- Satellite and Wireless Communication: Automation control panels at remote sites rely on communication technologies such as satellite, cellular, or radio frequency networks to transmit data to central control rooms. These networks ensure reliable data transmission and remote access, even in isolated locations.

- Redundant Communication Systems: Remote sites often operate in areas with limited connectivity, so control panels are equipped with redundant communication systems to ensure continuous data flow. If the primary communication link fails, the control panel can switch to a backup system, ensuring uninterrupted monitoring and control.

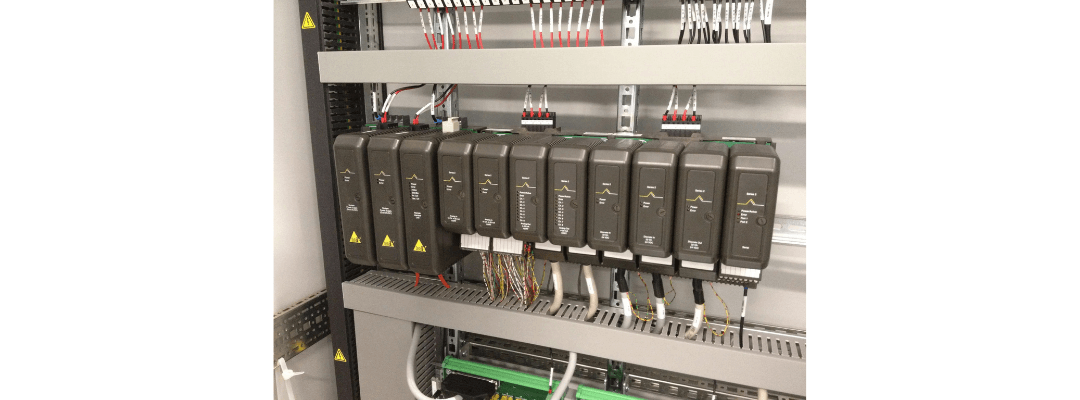

8. Adapting to Harsh Environmental Conditions

- Ruggedized Panels: Offshore and remote environments often subject equipment to extreme weather conditions, including high humidity, corrosive saltwater, and temperature fluctuations. Automation control panels used in these settings are designed with rugged enclosures that protect sensitive electronics from environmental damage, ensuring reliable operation.

- Weather Monitoring: Control panels integrate with weather monitoring systems to track conditions like wind speed, temperature, and humidity. If adverse weather is predicted, the system can automatically adjust operations, such as shutting down wind turbines during storms or securing equipment in advance of high winds.

9. Cybersecurity for Remote Sites

- Secure Remote Access: Remote sites are increasingly reliant on digital networks, making cybersecurity a top priority. Automation control panels for offshore and remote operations integrate secure communication protocols, such as Virtual Private Networks (VPNs) and data encryption, to protect against cyber threats.

- Firewall and Intrusion Detection: Automation systems are equipped with firewalls and intrusion detection mechanisms to monitor for unauthorized access or cyberattacks. These features help prevent disruptions to critical operations and safeguard valuable data from being compromised.

10. Scalability and Flexibility for Multiple Sites

- Managing Multiple Sites: Automation control panels allow operators to monitor and control multiple remote sites from a centralized location. This capability is critical for industries like oil and gas, where companies may operate several offshore platforms or pipelines spread across vast distances.

- Modular Design: Many automation control panels are designed with modularity in mind, allowing them to be easily expanded or reconfigured as operational needs evolve. For example, as new equipment is added to a site, it can be seamlessly integrated into the existing control system without requiring a complete overhaul.

Conclusion

Automation control panels are crucial for managing the efficiency, safety, and environmental compliance of offshore and remote operations. By enabling real-time monitoring, remote control, predictive maintenance, and safety interventions, these panels reduce the need for on-site personnel, minimize operational risks, and optimize energy usage. As industries increasingly expand into challenging and isolated environments, the role of automation control panels in ensuring smooth, secure, and efficient operations will continue to grow, providing the necessary tools to manage complex systems remotely.

Recent Comments