A motion-based control panel board is designed to control and coordinate the movement of machinery and systems in applications such as robotics, automation, CNC machines, conveyor systems, packaging, and more. The control panel provides precise control over the position, speed, acceleration, and torque of motors or actuators to ensure smooth and accurate motion. To ensure reliable operation, these panels include various components that allow for precise control, monitoring, and safety.

Ideal Components and Functions of a Motion-Based Control Panel Board

- Motion Controller (Central Processing Unit)

- Function: The motion controller is the brain of the system. It processes input signals, interprets motion commands, and sends control signals to drive motors or actuators. It coordinates all aspects of motion control, such as position, speed, and acceleration.

- Key Features:

- Multi-axis control for coordinating the movement of multiple motors.

- Interpolation for smooth motion paths (linear, circular, etc.).

- Support for complex motion profiles (synchronized, path-following, etc.).

- Communication with PLCs, HMIs, and other devices using protocols like Ethernet/IP, PROFIBUS, CANopen, or Modbus.

- Servo Drives and Motor Drivers

- Function: Servo drives or motor drivers control the power delivered to the motor based on signals received from the motion controller. They regulate speed, torque, and position by adjusting the current and voltage supplied to the motor.

- Key Features:

- Closed-loop control: Using feedback from encoders or resolvers to precisely control motor position and speed.

- Support for various motor types: Drives can control servo motors, stepper motors, or DC/AC motors.

- Protection against overload, short circuits, and overvoltage.

- Integration with safety functions such as Safe Torque Off (STO).

- Motors (Servo Motors, Stepper Motors, etc.)

- Function: Motors convert electrical energy into mechanical motion. They are responsible for the actual movement in the system, whether it’s rotational or linear.

- Types:

- Servo Motors: Provide precise control of position, speed, and torque with high accuracy, often used in applications requiring fine control.

- Stepper Motors: Offer accurate, incremental movement, commonly used in positioning applications where open-loop control is sufficient.

- AC/DC Motors: Used for applications requiring simpler control or high power output.

- Key Features:

- High torque-to-inertia ratio for fast response.

- Precise positioning for applications requiring high accuracy.

- Smooth and stable operation at various speeds.

- Encoders or Resolvers

- Function: Encoders or resolvers provide feedback on the motor’s position, speed, and direction. This feedback allows the controller to adjust the motor’s performance in real-time to meet the desired motion profile.

- Types:

- Incremental Encoders: Provide position data relative to a starting point and are commonly used in applications where relative motion feedback is sufficient.

- Absolute Encoders: Provide unique position data at all points, used for applications where precise positioning is needed even after power cycles.

- Resolvers: Offer robust position feedback in harsh environments and are commonly used in industrial settings.

- Key Features:

- High-resolution feedback for accurate motion control.

- Compatibility with the motion controller and motor driver.

- Durable construction for industrial use.

- Programmable Logic Controller (PLC)

- Function: A PLC manages the overall system logic and communication between different parts of the motion control system. While the motion controller handles the motion-specific tasks, the PLC coordinates machine operations, including safety interlocks, sequencing, and general machine automation.

- Key Features:

- Real-time control of machine operations.

- Communication with motion controllers, HMIs, sensors, and actuators.

- Support for I/O modules, allowing integration with various field devices.

- High-speed processing for coordinating complex motion sequences.

- Human-Machine Interface (HMI)

- Function: The HMI provides a user-friendly interface for operators to monitor and control the motion system. It displays real-time data such as motor positions, speeds, alarms, and allows the user to adjust motion parameters like setpoints or speeds.

- Key Features:

- Graphical displays for monitoring system performance and motion profiles.

- Touchscreen or button interface for controlling motion sequences.

- Integration with the motion controller and PLC for seamless control.

- Alarms and notifications for system faults or performance issues.

- Power Supply Unit

- Function: The power supply unit (PSU) provides regulated power to the control panel and its components, including the PLC, motion controller, sensors, and drives.

- Key Features:

- Voltage and current ratings matched to the requirements of all control panel components.

- Overvoltage, overcurrent, and thermal protection to prevent damage to sensitive components.

- Redundant power supply options for systems requiring high reliability.

- Safety Relays and Safety Controllers

- Function: Safety relays or safety controllers ensure that the system operates safely by monitoring emergency stop (E-stop) buttons, safety interlocks, and other safety devices. They allow the motion system to shut down safely in case of a fault or emergency.

- Key Features:

- Safe Torque Off (STO) feature for instantly cutting power to motors, preventing unintentional movement.

- Support for safety sensors like light curtains, door interlocks, and emergency stop switches.

- Certification to safety standards like SIL (Safety Integrity Level) or PL (Performance Level).

- Sensors (Proximity Sensors, Limit Switches, etc.)

- Function: Sensors provide critical input data to the control panel, such as the position of moving parts, proximity to objects, and speed. These inputs are processed by the motion controller and PLC to adjust motion sequences or halt operations when necessary.

- Types:

- Proximity Sensors: Detect the presence of objects or components without physical contact.

- Limit Switches: Indicate when a machine part reaches a certain position, often used for end-of-travel limits.

- Photoelectric Sensors: Detect the presence or absence of objects using light.

- Key Features:

- High reliability and fast response time.

- Easy integration with the control system for real-time monitoring.

- Communication Modules

- Function: Communication modules allow the control panel to interface with other devices, such as additional motion controllers, HMIs, PLCs, or SCADA systems. These modules ensure that real-time data and commands are shared across the system for synchronized operations.

- Key Features:

- Support for industrial communication protocols like Ethernet/IP, PROFIBUS, Modbus, CANopen, or EtherCAT.

- High-speed data exchange for real-time control and feedback.

- Emergency Stop (E-stop) Button

- Function: The E-stop button is a safety feature that allows operators to immediately stop all motion and power to the motors in the event of an emergency.

- Key Features:

- Redundant wiring for reliability.

- Compliance with safety standards like IEC 60204.

- Positioned for easy access during operation.

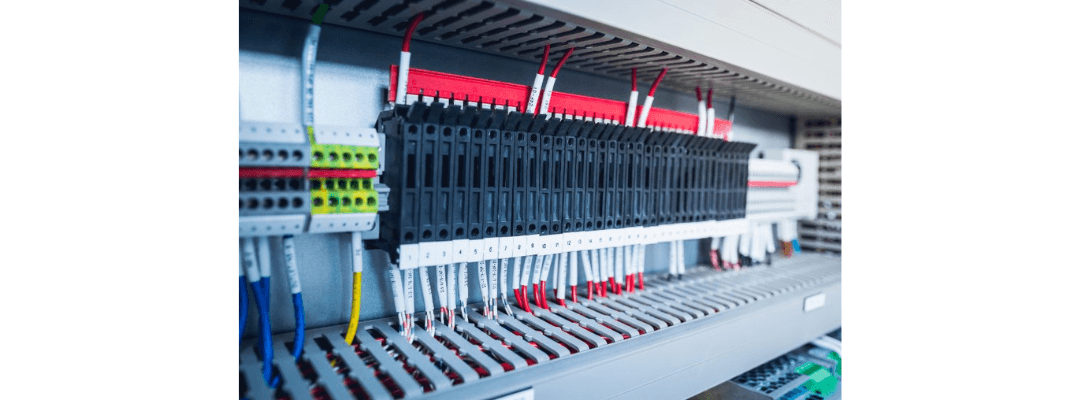

- Wiring and Cable Management

- Function: Proper wiring and cable management ensures the reliable transmission of power and control signals between components within the control panel.

- Key Features:

- Use of shielded cables to prevent electromagnetic interference (EMI) in high-frequency signal lines.

- Organized routing with cable trays and ducts for easy maintenance and troubleshooting.

- Color-coded wiring for clear identification of different signals (e.g., power, control, safety).

- Cooling and Ventilation

- Function: Cooling fans, heat sinks, or air-conditioning systems prevent overheating of the components inside the control panel. This is especially important for power-intensive components like servo drives and motors.

- Key Features:

- Properly sized ventilation or cooling systems for temperature regulation.

- Placement of fans or heat exchangers to maintain optimal airflow and component cooling.

Key Functions of a Motion-Based Control Panel

- Precise Motion Control

- Accurate control over position, speed, torque, and acceleration for single or multiple axes of motion.

- Coordination of complex motion tasks like interpolation (linear, circular), trajectory planning, and path-following.

- Synchronization

- Ability to synchronize the motion of multiple motors or actuators, ensuring that they work together to perform coordinated tasks like packaging, material handling, or robotic movements.

- Real-Time Feedback and Monitoring

- Continuous monitoring of motor positions, speed, and load through feedback devices like encoders or resolvers.

- Adjustment of motion in real-time based on feedback to maintain precision and prevent errors.

- Automation Integration

- Seamless integration with other automation systems, such as PLCs, SCADA systems, and HMIs, to provide comprehensive control of motion along with overall machine operations.

- Safety and Fault Management

- Real-time monitoring of safety sensors, E-stops, and interlocks to ensure safe operation.

- Automatic shutdown or torque control in the event of a fault, preventing damage or injury.

- Energy Efficiency

- Optimal use of power, particularly in motor control, by using features like regenerative braking or energy-efficient motor drivers.

- Flexibility and Scalability

- Ability to expand the system to include additional axes or motors as required by the application, making the control panel flexible and adaptable to future needs.

Conclusion

A motion-based control panel board combines various components such as motion controllers, servo drives, motors, sensors, and safety relays to provide precise, synchronized, and safe control of machinery. The system must offer real-time monitoring, feedback, and high-speed communication to ensure the accuracy of motion operations in a wide range of applications. Proper integration of control, safety, power management, and communication ensures the system is reliable, efficient, and adaptable for automation tasks in industries like manufacturing, robotics, packaging, and material handling.

Recent Comments