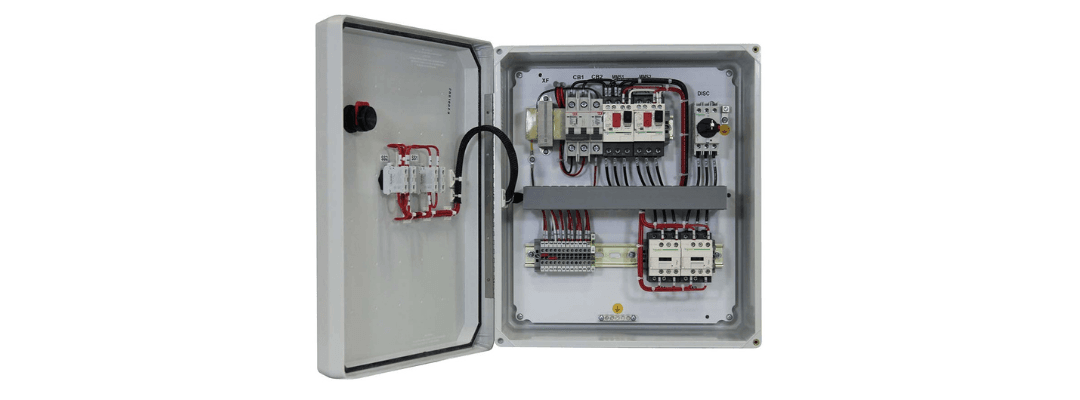

An electrical control panel serves as the central hub for controlling electrical systems in industrial, commercial, and residential applications. These panels manage power distribution, control devices, monitor systems, and provide protection against electrical faults. To ensure efficient, safe, and reliable operation, an electrical control panel is built with a range of essential components. Below are the ideal components and their functions of electrical control panels.

Ideal Components and Functions of an Electrical Control Panel

1.Main Circuit Breaker :

- Function: The main circuit breaker is the primary device that controls the flow of electricity into the control panel. It acts as a master switch and provides overcurrent protection for the entire electrical system. In case of a fault (e.g., short circuit or overload), the breaker trips to prevent damage to the electrical components.

- Ideal Property: It should be easily accessible and rated to handle the maximum current load of the system.

2. Surge Protection Device (SPD) :

- Function: The surge protection device safeguards electrical components from voltage spikes and surges, such as those caused by lightning strikes or power surges from the grid. It diverts excess voltage to the ground to prevent damage to sensitive equipment.

- Ideal Property: SPDs should be rated for the appropriate voltage and surge current capacity to handle potential transient events in the specific environment.

3. Control Transformer :

- Function: The control transformer steps down the main voltage to a lower control voltage (e.g., 24V or 120V), which is needed to power the control devices and relays inside the panel. This ensures the safe operation of control circuits.

- Ideal Property: It should provide stable output voltage under varying load conditions and have adequate power capacity for all control devices in the system.

4. Programmable Logic Controller (PLC) :

- Function: A PLC is the brain of the control panel, managing automation and control logic. It receives inputs from sensors and devices, processes the data, and sends outputs to control relays, actuators, motors, and other equipment. PLCs handle complex control tasks such as timing, sequencing, and monitoring.

- Ideal Property: The PLC should have sufficient processing power, memory, and I/O capacity to handle current and future control logic requirements. It should support communication protocols like Modbus, Ethernet/IP, or PROFIBUS for easy integration with other systems.

5. Relays and Contactors :

- Function: Relays and contactors are electromechanical devices used to switch electrical circuits on and off. Relays are used for low-power control signals, while contactors are used for switching high-power loads such as motors, heaters, and pumps.

- Ideal Property: They should be rated for the voltage and current requirements of the load they control and provide reliable, long-term operation without excessive wear.

6. Overload Relays :

- Function: Overload relays protect motors and other electrical equipment from damage caused by excessive current or prolonged overcurrent conditions. When an overload is detected, the relay trips and disconnects the motor to prevent overheating or failure.

- Ideal Property: Overload relays should be adjustable and sensitive to different motor loads, with a reset feature to restore operation after the fault is cleared.

7. Variable Frequency Drive (VFD) :

- Function: A VFD controls the speed and torque of an AC motor by adjusting the frequency and voltage supplied to the motor. This enables precise control over motor performance, improving energy efficiency and reducing mechanical wear.

- Ideal Property: The VFD should be capable of handling the motor’s rated power and provide smooth speed control. It should also include built-in protection features such as overcurrent, overvoltage, and thermal protection.

8. Push Buttons and Selector Switches :

- Function: Push buttons allow operators to manually control equipment, such as starting or stopping motors or resetting alarms. Selector switches are used to change operating modes, such as switching between manual and automatic control.

- Ideal Property: These controls should be durable, easy to operate, and clearly labelled. They should also have proper ratings for voltage and current and provide tactile feedback for accurate operation.

9. Human-Machine Interface (HMI) :

- Function: The HMI provides a user-friendly interface for monitoring and controlling the electrical system. It displays real-time data such as system status, alarms, and performance metrics. Operators can use the HMI to adjust set points, view trends, and control equipment.

- Ideal Property: The HMI should be intuitive, with clear graphical displays and easy navigation. It should offer touchscreen or push-button interfaces and support communication with the PLC for data exchange.

10. Current Transformers (CTs) :

- Function: Current transformers are used to step down high currents to a lower, measurable level for metering and protection devices. CTs provide accurate current measurements to control devices and protection relays.

- Ideal Property: CTs should have a high level of accuracy, typically within 1% of the actual current. They should be rated for the maximum current expected in the circuit and provide safe, isolated measurements.

11. Power Meters and Gauges :

- Function: Power meters measure electrical parameters such as voltage, current, power factor, frequency, and energy consumption. These readings are essential for monitoring system performance, managing energy efficiency, and detecting potential faults.

- Ideal Property: Power meters should offer high accuracy, clear displays, and support data logging and communication with the PLC or SCADA system for centralized monitoring.

12. Terminal Blocks :

- Function: Terminal blocks are used for organizing and connecting wires within the control panel. They provide secure, structured connections for incoming and outgoing cables, allowing easy maintenance, modifications, and troubleshooting.

- Ideal Property: Terminal blocks should be clearly labelled, durable, and rated for the appropriate voltage and current. They should offer simple and reliable connections, with the ability to handle multiple wire types.

13. Fuses and Circuit Protection Devices :

- Function: Fuses and circuit breakers provide overcurrent protection to prevent damage to wiring, equipment, and the panel itself. Fuses blow when the current exceeds a specified level, while circuit breakers trip and can be reset after the fault is cleared.

- Ideal Property: These devices should be sized according to the load’s current rating and provide reliable protection. Circuit breakers should be easily accessible for manual resetting, while fuses should be located for quick replacement.

14. Wiring Ducts and Cable Management :

- Function: Wiring ducts and cable trays are used for organizing and routing cables within the panel, keeping the interior neat and reducing the risk of wiring errors or electrical faults.

- Ideal Property: These should allow for sufficient airflow to prevent overheating and ensure easy access for maintenance. Proper labelling and color-coding should be used to identify circuits.

15. Grounding and Bonding System :

- Function: The grounding system ensures all metal parts of the control panel and connected equipment are properly grounded, preventing electrical shocks and ensuring safety in the event of a fault. Bonding connects all conductive parts to the same ground potential, reducing the risk of stray voltage.

- Ideal Property: The grounding system should comply with electrical safety standards (e.g., NFPA 70 or IEC standards) and provide a low-resistance path to earth for fault currents.

16. Cooling and Ventilation :

- Function: Cooling fans, air vents, or heat exchangers are used to dissipate heat generated by components like PLCs, VFDs, and relays, preventing overheating and ensuring optimal operating conditions.

- Ideal Property: The cooling system should be sufficient to maintain a safe operating temperature within the panel, especially in environments with high heat loads or continuous operation.

17. Communication Modules

- Function: Communication modules allow the control panel to interface with other systems, such as SCADA, BMS (Building Management System), or external control devices. These modules support data exchange and remote monitoring.

- Ideal Property: Communication modules should support common industrial protocols like Modbus, PROFIBUS, Ethernet/IP, or CAN bus, ensuring compatibility with other automation systems.

18. Alarms and Indicators :

- Function: Alarms and pilot lights indicate the status of the system, providing visual or audible alerts for conditions like overloads, faults, or process failures. They help operators take corrective action before issues become critical.

- Ideal Property: Alarms should be easily visible and audible, with color-coded lights to indicate normal operation (green), warnings (amber), or faults (red).

Recent Comments