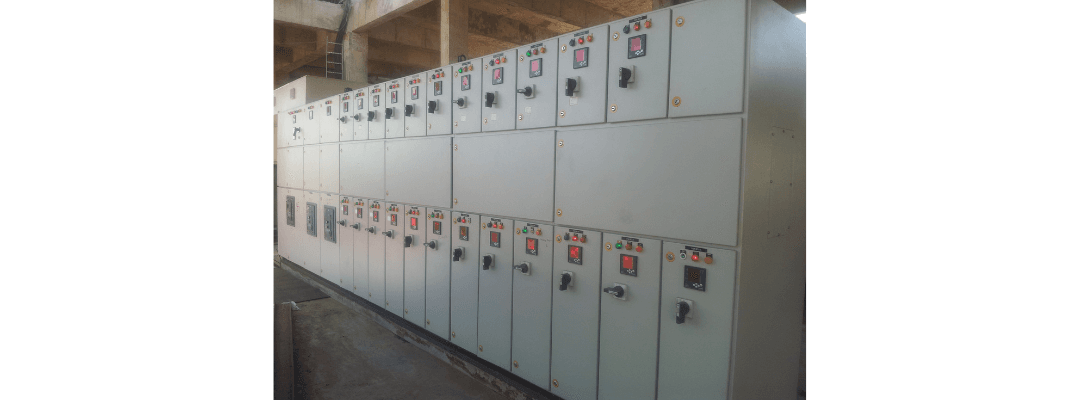

A Low Tension (LT) panel is an electrical distribution panel that operates at low voltage levels (typically below 1,000 volts). It is used to distribute and control electrical power to various loads in industrial, commercial, and residential facilities. LT panels are designed to handle low voltage power from transformers, generators, or utility grids and distribute it efficiently to different equipment, motors, lighting, and appliances. They also protect electrical systems from faults such as overloads, short circuits, and voltage fluctuations.

Key Functions of a Low Tension (LT) Panel

- Power Distribution:

- LT panels distribute power from a low-voltage source (such as a transformer or generator) to various loads like motors, lighting, and other electrical devices. They serve as the main point of control and distribution for electrical power within a facility.

- Protection Against Electrical Faults:

- LT panels are equipped with protective devices such as circuit breakers, fuses, and overload relays to safeguard electrical circuits and equipment from faults such as overcurrent, short circuits, and ground faults.

- Control of Electrical Loads:

- LT panels provide centralized control for electrical loads such as motors, pumps, and lighting systems. Operators can switch loads on or off and monitor their status from the panel.

- Metering and Monitoring:

- LT panels include meters to monitor electrical parameters such as voltage, current, power factor, and energy consumption. This data helps in managing energy usage, detecting faults, and ensuring the system operates efficiently.

- Power Factor Correction:

- Many LT panels are integrated with power factor correction (PFC) capacitors, which help improve the power factor of the electrical system. This reduces energy losses and avoids penalties from utility providers for low power factor operation.

- Safety and Compliance:

- LT panels are designed with built-in safety features such as emergency stop buttons, interlocks, and alarms to ensure safe operation and compliance with electrical standards and regulations.

Key Components of an LT Panel

- Circuit Breakers (ACBs/MCCBs/MCBs):

- Function: Circuit breakers protect the system from overcurrent and short circuits by automatically disconnecting power during a fault. They ensure the safety of both the system and connected equipment.

- Types:

- Air Circuit Breakers (ACBs) for higher current ratings.

- Molded Case Circuit Breakers (MCCBs) for medium current ratings.

- Miniature Circuit Breakers (MCBs) for lower current ratings.

- Busbars:

- Function: Busbars are conductive strips or bars that distribute electrical power to various outgoing circuits from the main power source. They handle high current loads and provide efficient power distribution within the panel.

- Relays and Contactors:

- Function: Relays and contactors control the switching of electrical loads, such as motors, and provide protection against overloads and voltage fluctuations. They automate the operation of electrical equipment by controlling power flow.

- Energy Meters:

- Function: Energy meters monitor and record electrical parameters such as voltage, current, power factor, and energy consumption. They provide valuable data for energy management and fault detection.

- Power Factor Correction (PFC) Capacitors:

- Function: PFC capacitors improve the power factor of the electrical system by reducing reactive power. This helps reduce energy losses and avoids penalties imposed by utility companies for poor power factor performance.

- Voltage and Current Transformers (VTs/CTs):

- Function: Voltage transformers (VTs) and current transformers (CTs) step down high voltages and currents to measurable levels for meters and protection devices, enabling accurate monitoring and control of the electrical system.

- Protection Devices (Overload Relays, Fuses):

- Function: Overload relays and fuses protect electrical equipment from overloading by disconnecting power when the current exceeds the safe limit. They prevent overheating and damage to the equipment.

- Indicating Lamps and Alarms:

- Function: Indicating lamps and alarms provide visual and audible signals to alert operators of system faults or abnormal operating conditions. These features help in troubleshooting and preventing further damage.

- Programmable Logic Controllers (PLCs) (Optional):

- Function: PLCs can be used in LT panels to automate and control complex electrical processes. They provide advanced monitoring and control functionality, such as load management and fault diagnosis.

Applications of Low Tension (LT) Panels

- Industrial Plants:

- Application: LT panels are widely used in industrial facilities for distributing power to heavy machinery, motors, and processing equipment. They provide centralized control for managing and protecting the electrical system in industries such as manufacturing, mining, cement, and steel.

- Example: In a manufacturing plant, LT panels distribute power to motors, conveyor belts, and other production machinery while providing overload protection.

- Commercial Buildings:

- Application: In commercial establishments like shopping malls, office complexes, and hotels, LT panels manage power distribution to lighting systems, HVAC units, elevators, and other electrical loads.

- Example: A shopping mall uses LT panels to control the power supply for lighting, air conditioning, and escalators, ensuring efficient energy usage.

- Residential Complexes:

- Application: LT panels are used in large residential complexes to distribute power to common areas, apartments, elevators, and backup systems. They ensure reliable power distribution and protect electrical systems from faults.

- Example: A residential complex uses an LT panel to distribute power to apartments, parking lot lighting, and water pumps, ensuring smooth operation.

- Healthcare Facilities:

- Application: Hospitals and healthcare facilities rely on LT panels for managing power supply to critical systems such as medical equipment, lighting, HVAC, and backup power. They provide continuous power and ensure the safety of electrical systems in critical environments.

- Example: A hospital uses LT panels to distribute power to medical imaging equipment, surgical rooms, and backup generators, ensuring continuous operation during outages.

- Data Centers:

- Application: Data centers require reliable power distribution to ensure continuous operation of servers, cooling systems, and backup generators. LT panels help manage power supply to critical equipment while providing monitoring and protection.

- Example: A data center uses LT panels to control power distribution to server racks and cooling systems, preventing downtime due to electrical faults.

- Educational Institutions:

- Application: Schools, universities, and educational campuses use LT panels to distribute power to classrooms, laboratories, libraries, and administrative buildings. They ensure efficient and safe power distribution across large campuses.

- Example: A university uses LT panels to manage power for lighting, HVAC systems, computer labs, and administrative offices, ensuring smooth operation.

- Renewable Energy Systems:

- Application: In renewable energy systems such as solar and wind farms, LT panels are used to manage the distribution of low-voltage power generated by the system. They also protect the system from faults and ensure smooth integration with the grid.

- Example: A solar power plant uses LT panels to distribute power from solar inverters to the grid and manage the power consumption of auxiliary systems.

- Infrastructure Projects:

- Application: Large infrastructure projects, such as airports, railways, and metro stations, rely on LT panels to distribute power to lighting, escalators, ventilation systems, and other essential services.

- Example: An airport uses LT panels to control power distribution to runway lighting, baggage handling systems, and passenger terminals, ensuring reliable operation.

Benefits of LT Panels

- Efficient Power Distribution:

- LT panels ensure that electrical power is distributed efficiently to various loads, optimizing energy usage and reducing power losses.

- Protection Against Faults:

- LT panels protect electrical systems from faults such as overcurrent, short circuits, and voltage fluctuations, ensuring the safety of both the equipment and personnel.

- Improved Power Factor:

- LT panels with power factor correction capacitors improve the power factor, reducing reactive power and lowering energy costs.

- Centralized Control:

- LT panels provide a centralized point of control for managing electrical loads, making it easier to monitor and control power usage across the facility.

- Customization and Flexibility:

- LT panels can be customized based on specific requirements, allowing for flexible configuration to suit different applications and power distribution needs.

- Data Monitoring and Reporting:

- LT panels equipped with energy meters and monitoring devices provide real-time data on power consumption and system performance, enabling better energy management and fault diagnosis.

- Safety Compliance:

- LT panels are designed to comply with safety standards and regulations, ensuring safe operation in industrial, commercial, and residential settings.

Conclusion

Low Tension (LT) panels are essential for managing and distributing electrical power in various applications, including industrial plants, commercial buildings, residential complexes, and renewable energy systems. They provide efficient power distribution, protect electrical systems from faults, and offer centralized control and monitoring of electrical loads. LT panels are widely used across industries to ensure the safe, reliable, and efficient operation of electrical systems, helping to improve energy management and reduce downtime.

Recent Comments