Reducing Energy Costs with Automation Control Panels in Commercial Buildings

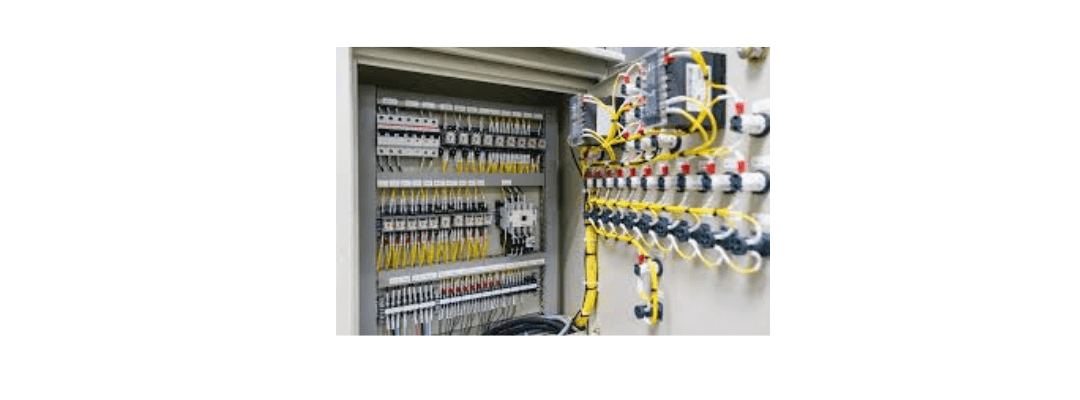

Automation control panels play a critical role in managing energy use efficiently in commercial buildings. By automating heating, ventilation, air conditioning (HVAC), lighting, and other energy-consuming systems, control panels help businesses minimize energy waste, lower operational costs, and optimize the comfort and functionality of their buildings. Here’s how automation control panels can be utilized to reduce energy costs in commercial buildings:

1. Automating HVAC Systems for Energy Efficiency

- Temperature Control and Zoning: Automation control panels enable precise control over HVAC systems, adjusting temperature settings based on occupancy, time of day, and ambient conditions. This prevents overcooling or overheating and reduces energy waste. Zoning allows different areas of the building to be controlled separately, ensuring that energy is only used where it is needed.

- Occupancy-Based Adjustments: By integrating occupancy sensors, automation systems can detect when rooms or spaces are not in use and adjust HVAC systems accordingly. This ensures that heating or cooling is reduced when areas are unoccupied, significantly cutting energy consumption.

- Variable Speed Drives (VSDs): Control panels can integrate Variable Speed Drives (VSDs) to control the speed of HVAC motors, pumps, and fans based on real-time demand. VSDs reduce energy use by running motors at lower speeds when full capacity is not needed, which is especially effective in HVAC systems.

2. Optimizing Lighting Systems

- Lighting Automation and Scheduling: Automation control panels can control lighting systems to turn on, dim, or turn off lights based on predefined schedules or occupancy levels. By automating lighting, energy consumption is minimized during off-hours or when spaces are not in use.

- Daylight Harvesting: Control panels can integrate sensors that detect natural light levels and adjust artificial lighting accordingly. When sufficient daylight is available, indoor lighting can be dimmed or turned off, reducing electricity use.

- Smart Lighting Zones: Zoning in lighting control allows different areas of the building to have independent lighting controls. For instance, high-traffic areas may have more lighting, while rarely used spaces can have minimal lighting, optimizing overall energy use.

3. Energy Management in Building Systems

- Energy Consumption Monitoring: Automation control panels provide real-time monitoring of energy consumption across various systems such as HVAC, lighting, elevators, and water pumps. By analyzing this data, building managers can identify inefficiencies and optimize energy use based on the actual performance of these systems.

- Demand Response: Control panels can be programmed to participate in demand response programs, adjusting energy consumption during peak periods when electricity rates are higher. For example, non-essential systems can be powered down or energy-intensive operations can be shifted to off-peak hours, reducing energy costs.

4. Managing Building Ventilation and Air Quality

- Demand-Controlled Ventilation (DCV): Control panels can regulate ventilation systems based on CO2 levels, humidity, or occupancy. By adjusting airflow in response to real-time demand, the system ensures optimal air quality while minimizing the energy used by ventilation fans and air handling units (AHUs).

- Variable Air Volume (VAV) Systems: For buildings with VAV HVAC systems, automation panels control air delivery based on room-by-room demand. This optimizes energy use by providing the necessary airflow to maintain comfort without overloading the HVAC system.

5. Integration with Renewable Energy Systems

- Solar Energy Optimization: In buildings equipped with solar panels, automation control panels manage energy flow between the solar generation system, energy storage (if available), and the building’s electrical systems. By prioritizing the use of solar power during peak sunlight hours, buildings can reduce reliance on grid electricity, thus lowering energy costs.

- Energy Storage Systems (ESS): Automation panels can also manage energy storage systems, ensuring that excess energy produced by solar panels is stored for use during peak demand periods or when grid energy prices are high. This helps flatten peak energy usage and reduces utility costs.

6. Power Management and Load Shedding

- Load Management: Automation control panels allow for the optimization of power usage by automatically adjusting or shedding non-critical loads during periods of high energy demand. For example, when electricity costs rise or peak load limits are reached, control panels can temporarily shut down non-essential systems to avoid costly demand charges.

- Peak Shaving: By monitoring the building’s overall energy consumption and predicting when peak demand will occur, control panels can initiate peak shaving strategies. This might involve reducing HVAC system operation, adjusting lighting levels, or leveraging energy storage systems to reduce grid dependency during peak hours.

7. Energy-Efficient Water Heating and Cooling

- Water Heating Automation: Automation panels can manage hot water systems based on demand and time-of-use schedules. For instance, heating water during off-peak electricity hours and storing it for use during peak demand periods can help lower energy costs.

- Chiller and Cooling Tower Control: In commercial buildings with cooling towers and chillers, automation control panels optimize their operation by adjusting water temperature, fan speeds, and pump operation based on real-time cooling needs. By reducing unnecessary energy use in cooling systems, buildings can significantly lower their electricity bills.

8. Predictive Maintenance for Energy-Intensive Systems

- Monitoring Equipment Health: Automation control panels equipped with predictive maintenance capabilities continuously monitor the performance of energy-intensive equipment such as HVAC units, pumps, and lighting systems. Early detection of inefficiencies or faults helps maintain optimal performance, reducing energy waste caused by malfunctioning or overworked equipment.

- Proactive Repairs: By detecting anomalies in equipment behavior, predictive maintenance allows building managers to schedule repairs or replacements before equipment fails, ensuring energy-efficient operation and preventing sudden increases in energy consumption due to failing components.

9. Integration with Building Management Systems (BMS)

- Centralized Control: Automation control panels can be integrated with a Building Management System (BMS) to centralize the control of multiple systems—HVAC, lighting, security, elevators, and energy management—under one platform. This allows for better coordination between systems, ensuring that energy use is optimized across the entire building.

- Coordinated Energy Management: By integrating all building systems, the BMS can dynamically adjust energy use based on real-time data. For instance, the HVAC system may reduce cooling when fewer occupants are detected by the building’s access control system, leading to energy savings.

10. Energy Reporting and Compliance

- Energy Auditing and Reporting: Automation control panels generate detailed energy usage reports, enabling building managers to conduct energy audits and identify areas for improvement. These reports can also be used for tracking progress toward energy efficiency goals, verifying utility bills, or meeting compliance requirements for energy standards like LEED or ENERGY STAR certifications.

- Utility Bill Management: Automation systems can track energy consumption in real time, helping building managers better understand their energy bills and reduce charges by optimizing system performance.

11. Smart Metering and Energy Analytics

- Smart Meters: Automation control panels often integrate with smart meters to provide detailed insights into energy consumption patterns. Smart meters allow buildings to track real-time energy use, giving managers the information needed to adjust energy loads or identify energy wastage.

- Data Analytics for Energy Efficiency: By analyzing energy data collected over time, automation systems can identify inefficiencies in building operations. This data-driven approach allows for continuous improvement, helping to implement energy-saving strategies such as reducing equipment runtime, optimizing HVAC cycles, or identifying underperforming assets.

Conclusion

Automation control panels provide powerful tools for reducing energy costs in commercial buildings by optimizing the operation of HVAC systems, lighting, ventilation, and other energy-intensive systems. Through real-time monitoring, intelligent control, and integration with renewable energy sources, automation systems help businesses lower utility bills, reduce their carbon footprint, and maintain optimal comfort for occupants. As energy prices rise and sustainability becomes increasingly important, investing in automation control panels is a smart strategy for improving the energy efficiency and overall profitability of commercial buildings.

Recent Comments