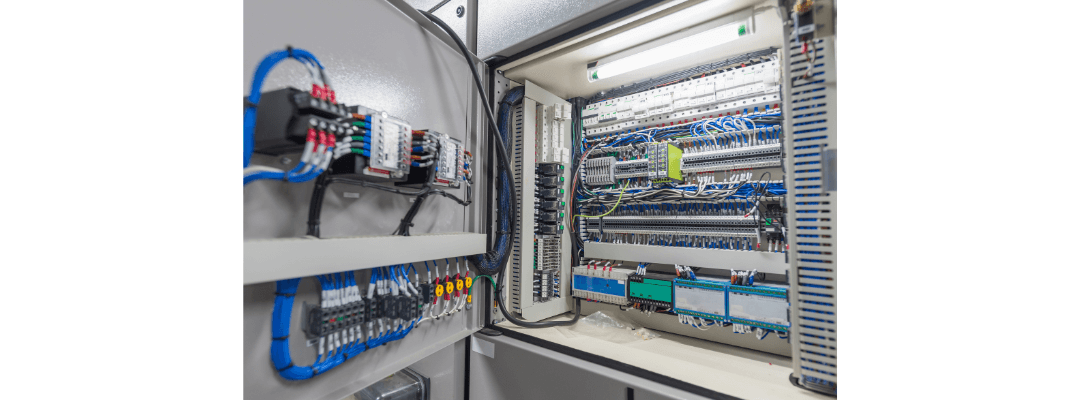

Electrical control panels play a critical role in the operation of an Energy Management System (EMS) by serving as the central hub for controlling, monitoring, and optimizing the electrical systems within a facility. They facilitate the integration of energy management strategies that improve energy efficiency, reduce operational costs, and ensure reliable power distribution. Below are the key roles and contributions of electrical control panels in an energy management system:

1. Power Distribution and Load Management

- Centralized Control: Electrical control panels distribute power to different areas of a facility, managing the flow of electricity to lighting, HVAC systems, motors, pumps, and other critical equipment. Through precise control over circuit breakers, relays, and contactors, the panel ensures that power is delivered efficiently.

- Load Shedding: In an EMS, the control panel can implement load shedding strategies, where non-essential loads are automatically reduced or disconnected during peak demand periods. This helps prevent overloading, reduces energy consumption during high-cost periods, and helps avoid demand penalties imposed by utility companies.

- Demand Response: Electrical control panels work in conjunction with EMS software to adjust the operation of equipment based on real-time energy demand. This ensures that power consumption is optimized and balanced across various systems.

2. Energy Monitoring and Data Collection

- Real-Time Energy Monitoring: Electrical control panels are equipped with energy meters and sensors that continuously monitor power usage, voltage, current, power factor, and other key electrical parameters. This data is transmitted to the EMS, allowing operators to gain insights into energy consumption patterns and identify opportunities for optimization.

- Data Logging: Control panels can store energy usage data, which the EMS analyzes to track long-term consumption trends, identify energy wastage, and benchmark performance against energy goals. This information helps in the formulation of strategies for reducing energy consumption and improving efficiency.

- Power Quality Monitoring: The control panel tracks power quality metrics such as voltage dips, harmonic distortion, and phase imbalances. Maintaining good power quality helps prevent equipment malfunctions, reduces downtime, and enhances overall system efficiency.

3. Power Factor Correction

- Power Factor Improvement: Many electrical control panels are integrated with power factor correction (PFC) systems, which automatically engage capacitors to improve the power factor. A poor power factor leads to inefficient energy use and higher utility bills. By improving power factor, the panel helps reduce energy losses and avoids penalties for low power factor imposed by utility companies.

- Energy Cost Savings: With better power factor correction, electrical systems consume less reactive power, improving overall efficiency and lowering energy consumption, which leads to cost savings.

4. Energy Efficiency and Optimization

- Control of Variable Frequency Drives (VFDs): Electrical control panels often house Variable Frequency Drives (VFDs) that optimize motor speed and torque based on load requirements. VFDs help reduce energy consumption in systems such as pumps, fans, and conveyors by adjusting the speed of the motor instead of operating at full power continuously.

- Soft Starters: By reducing the initial surge of current during motor startup, soft starters minimize electrical and mechanical stress, saving energy and extending the lifespan of equipment.

- Load Prioritization: Control panels enable the prioritization of energy usage across various systems and processes, allowing for more energy-efficient operations by powering down non-essential systems during periods of low demand.

5. Automation and Process Control

- Automated Scheduling: Electrical control panels enable the automation of lighting, HVAC, and machinery based on pre-set schedules. By automating these systems, energy usage is minimized during non-peak times, reducing waste. For example, lighting and HVAC systems can be programmed to operate only during working hours and automatically power down when not needed.

- Integration with Renewable Energy Sources: Electrical control panels can be integrated with renewable energy systems like solar panels or wind turbines. The EMS manages energy generation from these sources and optimizes their use to reduce dependence on grid power, further improving energy efficiency.

- Demand-Side Management: Electrical control panels help implement demand-side management strategies by controlling how and when energy is consumed. They can adjust equipment operation based on dynamic pricing from utility companies, ensuring that energy-intensive processes are run during low-cost periods.

6. Load Balancing and Peak Shaving

- Load Balancing: Electrical control panels ensure that power is distributed evenly across all systems, preventing overloading and ensuring a stable power supply. Balanced loads help prevent equipment wear and improve the reliability of the overall energy system.

- Peak Shaving: The EMS, with the help of the control panel, can implement peak shaving techniques by reducing power demand during peak periods. This is achieved by shifting non-essential loads to off-peak periods or temporarily reducing the power consumption of certain processes, leading to significant energy cost savings.

7. Energy Backup and Power Reliability

- Integration with Backup Generators: Electrical control panels can synchronize power from backup generators during outages, ensuring an uninterrupted power supply to critical systems. The EMS can manage the use of backup generators to minimize fuel consumption while maintaining reliability.

- Uninterruptible Power Supply (UPS): Control panels may be integrated with UPS systems to provide backup power during short-term outages, protecting sensitive equipment from power fluctuations and downtime.

8. Fault Detection and Diagnostics

- Fault Detection and Alarming: Electrical control panels monitor the performance of electrical systems and detect abnormalities, such as overcurrent, short circuits, phase imbalances, or voltage fluctuations. If a fault is detected, the panel can automatically disconnect the affected circuit and notify the EMS, ensuring quick response and minimizing downtime.

- Predictive Maintenance: The EMS, using data collected by the control panel, can implement predictive maintenance strategies. By analyzing the performance and condition of equipment, the EMS can predict when maintenance is needed, reducing unexpected breakdowns and optimizing the performance of electrical systems.

9. Remote Monitoring and Control

- Remote Access: With advancements in communication technologies, electrical control panels can be connected to the EMS via protocols such as Modbus, PROFIBUS, Ethernet/IP, or BACnet. This allows facility managers to remotely monitor energy usage, control equipment, and adjust settings from a central control room or offsite location.

- Real-Time Control: Remote access allows operators to make real-time adjustments to equipment settings, power distribution, and system operation based on current energy demand and usage data. This improves flexibility and responsiveness in managing energy consumption.

10. Energy Auditing and Reporting

- Energy Auditing: Control panels provide real-time data to the EMS, allowing for continuous energy audits. This helps identify inefficient processes, unoptimized energy usage, and areas for improvement. The data can be used to benchmark performance and set energy-saving goals.

- Reporting and Analytics: Electrical control panels collect and relay data to the EMS, where it is analyzed to generate reports on energy usage, cost savings, and system performance. These reports help facility managers make informed decisions about energy conservation and efficiency improvements.

Conclusion

Electrical control panels play a central role in Energy Management Systems (EMS) by managing the distribution and optimization of electrical power, monitoring energy consumption, and ensuring system reliability. Through intelligent automation, real-time monitoring, load management, power factor correction, and fault detection, control panels help reduce energy waste, improve efficiency, and lower operational costs. They are essential for implementing modern energy management strategies, enabling facilities to optimize their energy use, minimize costs, and contribute to sustainable operations.

Recent Comments