Designing an automation control panel requires careful consideration of various factors to ensure that the system operates efficiently, safely, and reliably. Whether the panel is being designed for industrial machinery, HVAC systems, pumps, or any other automated process, the following key aspects should be taken into account:

1. Understanding the Application and System Requirements

- Process Needs: Define the specific application and functional requirements of the control panel, including the type of equipment, system complexity, and control logic. The panel should meet the operational goals of the system, whether it’s controlling a manufacturing process, HVAC system, or water treatment plant.

- Input and Output Devices: Determine the types and number of input/output (I/O) devices (e.g., sensors, switches, motors, relays, actuators) that need to be connected to the control panel. This helps in selecting the right size and configuration for the panel.

- Environment Conditions: Consider the environment where the control panel will be installed, such as temperature, humidity, dust, and potential exposure to chemicals or water. Choose materials and components that are suitable for the operational environment.

2. Safety Considerations

- Standards Compliance: Adhere to relevant safety standards such as UL 508A and IEC 61439 to guarantee electrical safety and performance.

- Protective Devices: Integrate circuit breakers, overload relays, and fuses to shield the panel from electrical faults.

- Emergency Systems: Implement emergency stop systems and safety interlocks for secure shutdown during emergencies.

- Arc Flash Protection: Consider arc flash mitigation for systems handling high-voltage components to reduce the risk of arc flash events.

3. Component Selection

- Programmable Logic Controllers (PLC): Choose the appropriate PLC based on system complexity, I/O count, and the level of automation needed. Ensure the PLC has enough processing power and memory to handle the control logic and future upgrades.

- Human-Machine Interface (HMI): If operator control and visualization are required, select an HMI that provides a user-friendly interface for real-time monitoring and control. The HMI should allow operators to adjust settings, view alarms, and access historical data easily.

- Power Supply: Design a reliable and adequately rated power supply to support all components within the panel. If the system is mission-critical, consider adding redundant power supplies or Uninterruptible Power Supply (UPS) systems to ensure continuous operation during power outages.

- Relays, Contactors, and Drives: Select high-quality relays, contactors, and Variable Frequency Drives (VFDs) based on the load requirements of motors, actuators, and other devices being controlled.

4. Panel Layout and Component Placement

- Space Optimization: Lay out the components in a way that optimizes the space within the enclosure. Ensure there is adequate space for wiring, future expansion, and heat dissipation.

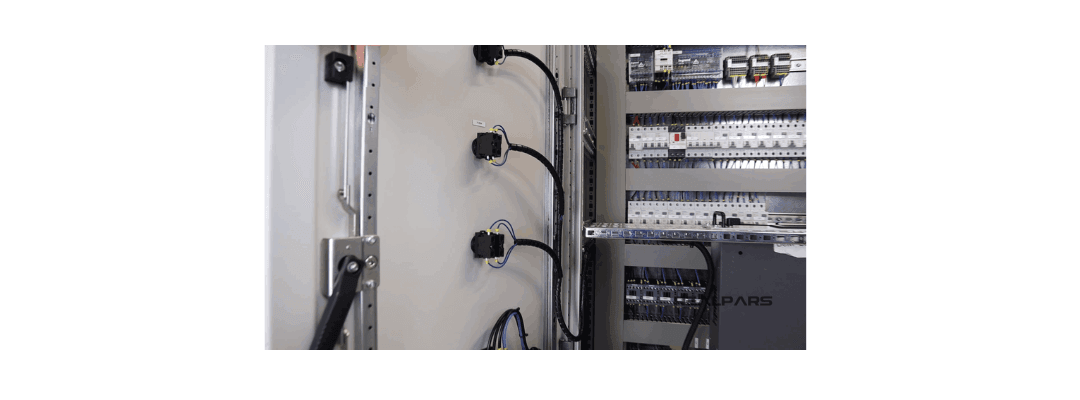

- Accessibility and Maintenance: Arrange components for easy access, making maintenance and troubleshooting easier. Ensure critical components such as circuit breakers, fuses, and terminal blocks are easily accessible without dismantling the entire panel.

- Component Separation: Separate power, control, and signal components to minimize electromagnetic interference (EMI) and ensure safe operation. High-voltage components should be kept away from low-voltage controls and communication lines.

- Wire Routing: Plan wire routing carefully to avoid clutter and ensure proper signal transmission. Use wire ducts or cable trays to organize wires neatly and provide clear labeling for ease of identification.

5. Electrical Design and Wiring Considerations

- Circuit Protection: Include circuit breakers, fuses, and surge protectors in the design to protect against overcurrent and voltage spikes. Each circuit in the panel should have proper protection based on the load it serves.

- Proper Grounding: Ensure that the control panel is grounded correctly to prevent electrical shocks and protect equipment from voltage surges or lightning strikes. Proper grounding is also essential to reduce noise and EMI in sensitive control circuits.

- Cable Sizing: Select cables of appropriate gauge to handle the current load for each component. Incorrect sizing can result in overheating, voltage drops, or power loss, leading to inefficiencies and safety hazards.

- Signal Isolation: Use signal isolation techniques like optocouplers or isolation transformers to separate control signals from high-power electrical circuits, improving safety and reducing noise interference.

6. Thermal Management

- Ventilation and Cooling: Ensure that the control panel is adequately ventilated and cooled to prevent overheating. Use fans, heat sinks, or air conditioners as needed, especially if the panel is installed in a high-temperature environment.

- Component Temperature Ratings: Select components that are rated for the environmental temperature range. Sensitive electronics, such as PLCs and HMIs, should be shielded from extreme temperatures to ensure long-term reliability.

- Thermal Analysis: Perform a thermal analysis of the control panel to ensure proper heat dissipation. This is particularly important for panels with high-power components like VFDs and motor starters.

7. Control and Communication

- Network and Communication Protocols: Ensure that the control panel supports the required communication protocols (e.g., Modbus, Ethernet/IP, PROFIBUS, BACnet) to integrate seamlessly with other systems like SCADA, DCS, or building management systems (BMS). Proper network connectivity allows for remote monitoring, diagnostics, and control.

- Fieldbus and I/O Expansion: If the system is large or expected to grow, use fieldbus communication or I/O expansion modules to accommodate future I/O requirements without rewiring the entire system.

8. Automation and Control Logic

- PLC Programming: Carefully program the control logic to meet the operational requirements, including automatic start/stop sequences, alarms, and interlocks. Ensure that the control logic is flexible enough for future upgrades or process changes.

- Redundancy in Control Systems: For critical systems, consider implementing redundant PLCs or control systems to ensure reliability in case of failures.

9. Human-Machine Interaction and User Accessibility

- HMI Interface Design: Design the HMI for user-friendliness, ensuring that operators can easily interpret data, access key controls, and troubleshoot issues. The layout should include alarms, warnings, status indicators, and real-time data monitoring.

- Remote Monitoring and Control: Incorporate remote monitoring features to allow operators to access and control the panel from a distance. This is particularly useful for large facilities or sites with limited on-site personnel.

10. Cybersecurity and Access Control

- Physical Security: Ensure the control panel is secured with lockable enclosures to prevent unauthorized access. Key operational switches and emergency stops should be clearly accessible but protected from tampering.

- Cybersecurity: If the panel has remote access capabilities or is connected to a network, implement cybersecurity measures such as firewalls, encryption, and VPNs to protect against unauthorized access, hacking, or malware attacks.

11. Documentation and Labeling

- Wiring Diagrams and Schematics: Provide clear and detailed wiring diagrams, schematics, and documentation of the control logic. Proper documentation ensures easier installation, troubleshooting, and maintenance.

- Component and Cable Labeling: Label all components, wires, and terminals clearly and consistently. This simplifies troubleshooting, repairs, and future expansion. Use permanent labels that can withstand the operational environment.

12. Testing and Validation

- Factory Acceptance Testing (FAT): Perform FAT before shipping the panel to ensure that all components function properly and the control logic is working as expected.

- Site Acceptance Testing (SAT): Conduct SAT once the panel is installed on-site to verify that it integrates correctly with the system and performs as designed in the actual operating environment.

- Compliance Testing: Ensure the control panel is tested and certified according to relevant electrical safety standards and industry regulations before commissioning.

13. Scalability and Future-Proofing

- Room for Expansion: Design the panel with future growth in mind. Include additional space and extra terminal blocks for future wiring, and ensure the PLC and I/O modules can accommodate future upgrades.

- Modular Design: Consider using a modular design so that sections of the panel can be easily updated, replaced, or expanded without affecting the entire system.

Recent Comments