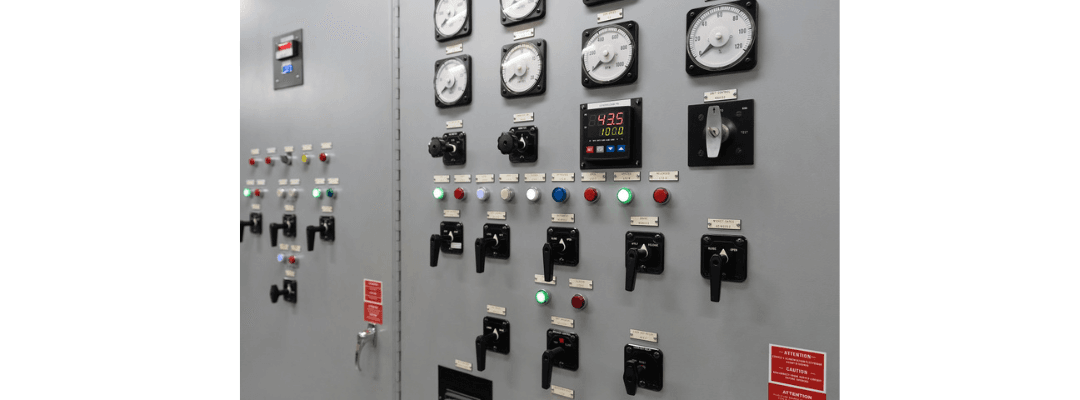

Automation control panels are crucial components in industrial and commercial automation systems. They manage, monitor, and control various processes, machinery, and systems. There are several types of automation control panels designed to meet specific application needs, each with distinct functionalities and components. Below are the most common types of automation control panels and their uses:

1. Programmable Logic Controller (PLC) Panels

Description:

PLC panels are one of the most widely used types of automation control panels in industrial environments. A PLC (Programmable Logic Controller) is a digital computer designed to control manufacturing processes, such as assembly lines, robotic devices, or any activity requiring high reliability, ease of programming, and process fault diagnosis.

Key Features:

- Uses a PLC as the central processing unit (CPU) to control machinery and processes.

- Can handle complex logic, timing, counting, and sequencing tasks.

- Provides inputs and outputs (I/O) for sensors and actuators.

- Highly flexible and programmable for various automation tasks.

Applications:

- Assembly lines

- Material handling systems

- Packaging equipment

- Industrial machinery control

- HVAC systems in large facilities

2. Motor Control Center (MCC) Panels

Description:

MCC panels are designed to control and protect electric motors in an industrial facility. They house multiple motor control units in a single enclosure and are commonly used for centralizing motor controls in manufacturing plants and industrial sites.

Key Features:

- Houses motor starters, overload relays, circuit breakers, and other control devices for motor protection and control.

- Can include Variable Frequency Drives (VFDs) and soft starters for advanced motor control.

- Provides centralized control of multiple motors, improving efficiency.

- Modular design allows for scalability and easy maintenance.

Applications:

- Water and wastewater treatment plants

- Pumping systems

- Conveyor systems

- Industrial plants with multiple motors

- Large-scale HVAC systems

3. Distributed Control System (DCS) Panels

Description:

DCS panels are used in large-scale industrial processes that require high levels of automation and control over multiple subsystems. A DCS typically divides control functions across various distributed controllers rather than relying on a single central controller.

Key Features:

- Provides distributed control across various sections of a process plant.

- Offers real-time monitoring, control, and data acquisition.

- Scalable architecture for large industrial systems.

- High-level integration with process instrumentation and safety systems.

Applications:

- Oil and gas refineries

- Chemical plants

- Power generation plants

- Pharmaceutical manufacturing

- Paper and pulp industries

4. Human-Machine Interface (HMI) Panels

Description:

HMI panels provide a graphical interface that allows operators to monitor and interact with the automated process. HMIs are often integrated into automation control systems to display real-time data, provide alerts, and offer control over machinery.

Key Features:

- Touchscreen display for user interaction.

- Provides real-time system status, alarms, and control options.

- Can be standalone or integrated with PLCs or DCS for centralized monitoring.

- Allows remote monitoring and diagnostics through network connectivity.

Applications:

- Monitoring and controlling industrial processes

- Building automation systems

- Factory floor data visualization

- Supervisory control and data acquisition (SCADA) systems

5. SCADA (Supervisory Control and Data Acquisition) Panels

Description:

SCADA panels are used to monitor and control large-scale processes across multiple sites. SCADA systems are designed to gather real-time data from various sensors and devices, often across geographically dispersed locations, and control them through centralized systems.

Key Features:

- Provides centralized control and data collection for distributed systems.

- Supports real-time monitoring, alarming, and reporting.

- Typically used for remote control and monitoring of industrial sites.

- Integrates with PLCs, RTUs (Remote Terminal Units), and sensors for process automation.

Applications:

- Electrical power distribution networks

- Water treatment plants

- Oil and gas pipelines

- Telecommunication networks

- Transport and logistics systems

6. Variable Frequency Drive (VFD) Panels

Description:

VFD panels control the speed of electric motors by adjusting the frequency and voltage supplied to the motor. They are commonly used in applications requiring variable motor speeds, such as fans, pumps, and conveyors.

Key Features:

- Controls motor speed, torque, and direction.

- Improves energy efficiency by reducing power consumption during low-demand periods.

- Reduces mechanical stress on motors, improving their lifespan.

- Allows for soft starting and stopping of motors.

Applications:

- HVAC systems

- Water pumping systems

- Conveyor systems

- Industrial fans and blowers

- Compressors

7. Remote I/O Panels

Description:

Remote I/O panels extend the reach of the main control panel by providing remote input and output terminals for sensors, actuators, and other field devices. These panels communicate with the main control panel through industrial communication protocols.

Key Features:

- Expands the I/O capacity of the main control system.

- Provides connectivity for sensors and actuators in remote or hard-to-reach locations.

- Reduces wiring complexity by consolidating remote signals.

- Communicates with PLCs or DCS via communication protocols such as PROFIBUS, Modbus, or Ethernet/IP.

Applications:

- Distributed industrial systems

- Oil and gas pipelines

- Water treatment facilities

- Process industries with multiple remote units

8. Power Control Center (PCC) Panels

Description:

PCC panels are used for distributing and controlling power in large industrial plants. These panels manage high power loads and offer protection for transformers, generators, and heavy machinery by providing overload, short circuit, and other safety features.

Key Features:

- Controls and monitors the power supply to various parts of a facility.

- Houses protective devices like circuit breakers and relays.

- Typically handles medium-voltage to low-voltage power distribution.

- Provides overload and fault protection for connected equipment.

Applications:

- Power distribution in large industrial plants

- Manufacturing plants

- Commercial buildings

- Electrical substations

9. Instrumentation Panels

Description:

Instrumentation panels house and manage various measurement and control instruments used in process industries. These instruments measure critical parameters such as pressure, temperature, flow, and level, providing real-time data to the control system for accurate process control.

Key Features:

- Houses process control instruments for measuring key process parameters.

- Provides centralized control and data acquisition from sensors and field devices.

- Integrates with PLCs or DCS for process automation.

- Includes alarms, indicators, and signal conditioners.

Applications:

- Chemical processing plants

- Oil and gas refineries

- Water treatment plants

- Power generation facilities

10. Annunciator Panels

Description:

Annunciator panels are used to alert operators to abnormal conditions or faults in an industrial process. These panels display visual and audible alarms to notify operators of the status of specific parameters or equipment failures.

Key Features:

- Provides real-time fault indication with visual and audible alerts.

- Typically used in conjunction with PLC or SCADA systems.

- Configurable to monitor a wide range of parameters.

- Helps in timely troubleshooting and minimizing downtime.

Applications:

- Power generation and distribution systems

- Water treatment plants

- Manufacturing processes

- HVAC systems

Conclusion

Each type of automation control panel serves a unique role in managing industrial processes, motor control, or power distribution, improving efficiency and safety. The choice of control panel depends on the specific application, complexity, and scale of the automation system. From PLC panels for machine control to DCS panels for large process plants, these control panels are essential components in modern industrial automation and play a crucial role in optimizing production, ensuring safety, and improving operational efficiency.

Recent Comments